Profile Grinding: Mastering Complex Precision

Introduction

Profile grinding is an advanced machining process critical for manufacturing intricate and precise shapes on workpieces. It serves as a cornerstone in industries that demand high precision, complex geometries, and superior surface finishes.

At Bay Union Abrasive Technology Co., Ltd., we excel in providing high-quality profile grinding wheels designed to meet diverse industrial needs, ensuring optimal precision, efficiency, and durability.

What is Profile Grinding?

Profile grinding involves the precision shaping of curved, grooved, or contoured surfaces using specialized grinding wheels. The process requires a combination of expertise and advanced tools to maintain tight tolerances and ensure consistent performance. This technique stands out for its ability to handle larger contact areas between the grinding wheel and the workpiece while effectively dissipating heat and retaining the shape of the grinding wheel.

Profile grinding is widely applied in industries where exacting standards are required, such as:

• Gear manufacturing: For producing intricate tooth profiles.

• Thread grinding: For creating precise industrial fasteners.

• Bearing production: For ensuring smooth rotational movement in mechanical systems.

Key Benefits of Profile Grinding

- Precision and Accuracy: Ensures tight tolerances, making it ideal for manufacturing components with detailed profiles.

- Superior Shape Retention: Maintains the wheel’s profile during extended use, ensuring consistent performance across production runs.

- Efficient Heat Management: Minimizes thermal damage to the workpiece, preserving material properties and enhancing tool longevity.

- High Surface Quality: Achieves smooth finishes that reduce the need for additional polishing or finishing processes.

- Versatility: Can machine a wide range of materials, including hardened steels, superalloys, and ceramics.

Applications of Profile Grinding Wheels

- Gear Manufacturing: Essential for shaping precise gear teeth that ensure smooth transmission and reduced wear. Profile grinding wheels are indispensable for producing high-performance gears in automotive and aerospace industries.

- Thread Grinding: Enables the accurate creation of screws, bolts, and fasteners with precise thread geometries. This application ensures compatibility and reliability in critical mechanical assemblies.

- Bearing Industry: Ideal for forming curved or grooved surfaces in bearings, which are crucial for minimizing friction and ensuring smooth operation.

- Tool and Die Making: Used to create and maintain intricate molds and dies, allowing for the production of high-quality components.

- Precision Engineering: Facilitates the production of complex, high-precision components, such as turbine blades, medical implants, and electronic devices.

- Optics and Semiconductors: Used for grinding lenses and wafer surfaces, where flawless finishes are mandatory.

Bay Union's Profile Grinding Wheels

Bay Union offers an extensive range of profile grinding wheels designed to meet modern manufacturing challenges:

- CKS Gear Grinding Wheel: Built with high self-sharpening abrasives and excellent heat dissipation, these wheels minimize surface burns while achieving precise gear profiles.

- BFV Gear Grinding Wheel: Combining SG abrasives with a low-temperature ceramic binder, this wheel maintains its microcrystalline structure for superior performance.

- GFV Gear Grinding Wheel: Featuring sharp fused alumina, this wheel is optimized for grinding ductile metals and ensures uniform abrasive exposure for consistent results.

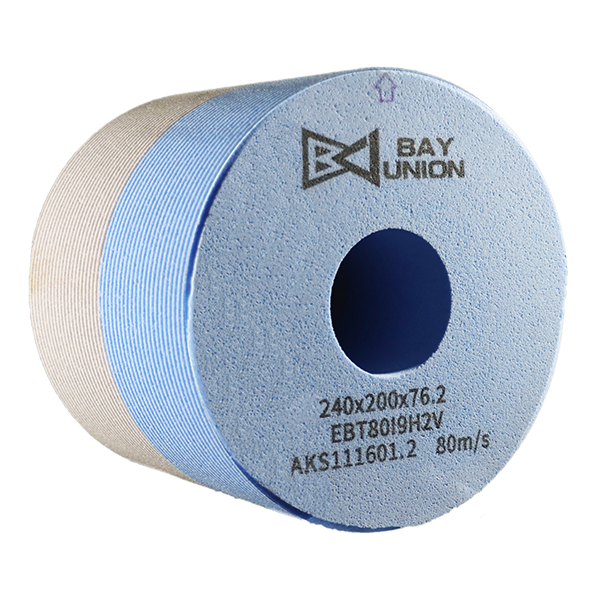

- Continuous Generating Grinding Series (EBT/BFW/GFW): Tailored for continuous gear grinding, these wheels effectively handle surface hardening treatments and ensure smooth gear profiles.

Our grinding wheels are crafted using advanced manufacturing techniques, ensuring they deliver precision, stability, and superior surface roughness in diverse applications.

Technological Advancements in Profile Grinding

Bay Union integrates cutting-edge technology into its profile grinding solutions to address evolving industry needs:

• Microcrystalline Abrasives: Enhance grinding efficiency and provide superior surface finishes.

• Customized Bonding Formulas: Improve heat dissipation, reduce wheel wear, and ensure longer service life.

• Smart Manufacturing Techniques: Enable consistent quality control and adaptability for custom orders.

Sustainability in Profile Grinding

As a responsible manufacturer, Bay Union prioritizes sustainability in all aspects of production. By using durable materials and optimizing production processes, we reduce waste and energy consumption. Our long-lasting grinding wheels contribute to environmentally friendly manufacturing practices by minimizing the frequency of replacements.

Why Choose Bay Union for Profile Grinding Solutions?

Bay Union is a trusted name in abrasive technology, offering products that combine innovation, durability, and precision. Here's why customers choose us:

• Custom Solutions: We tailor our grinding wheels to meet the unique requirements of your application.

• Technical Expertise: Our team of experts provides guidance to ensure optimal tool performance.

• Global Standards: We adhere to stringent quality standards, delivering reliable products for critical applications.

Conclusion

Profile grinding plays a vital role in modern manufacturing, enabling the creation of complex shapes and delivering superior surface finishes with precision. Bay Union's profile grinding wheels are at the forefront of this technology, designed to enhance efficiency, ensure reliability, and meet the most demanding industrial standards.

Explore Bay Union's product range to discover how our advanced profile grinding wheels can transform your manufacturing processes. Contact our team of experts to find the perfect solution for your precision grinding needs and achieve excellence in every project.