Bearing Industry

Grinding wheels have been used for a wide range of applications over the years. However, one industry that has benefited greatly from the use of grinding wheels is the bearing industry. Bearings are essential components in machinery and equipment like turbines, generators, and aircraft engines that rely on movement. They provide support and guide the motion of rotors, shafts, and other moving parts.

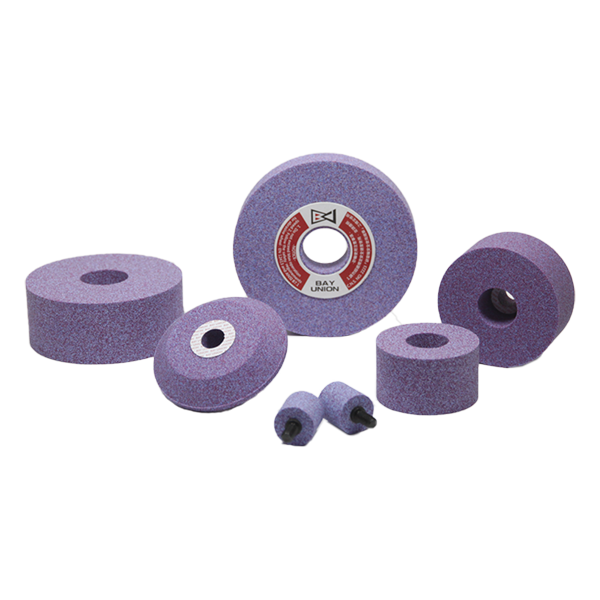

In the bearing industry, grinding wheels play a key role in the production process. Grinding wheels are used for grinding and finishing bearing surfaces, polishing and smoothing out rough edges and imperfections from the metal surface, and shaping the bearing components. Grinding wheels are often made of abrasive materials like aluminum oxide, silicon carbide, and diamond.

One of the most significant characteristics of grinding wheels for the bearing industry is their ability to produce consistent finishes. The use of grinding wheels guarantees that all bearing surfaces are finished to the required tolerances. Consistent surface finishes ensure that the bearings operate at optimal levels without any friction, heat generation, and wear and tear.

Grinding wheels are also used for producing the right surface roughness on bearings. The proper roughness can be achieved by selecting the abrasive grit and bond type for grinding the bearing surface. A consistent surface roughness is critical to reduce the wear and tear on the bearing, resulting in longer operating life and reduced maintenance costs.

Grinding wheels can be used on various bearing components, including inner and outer rings, balls, and rollers. The high precision and accuracy of these grinding wheels ensure that all components are uniformly sized and shaped, enhancing the bearing's performance and durability.

The bearing industry requires high-quality products that guarantee efficient and reliable machinery performance. Grinding wheels make it possible to achieve the level of performance that modern machinery and equipment require. Besides, grinding wheels are also environmentally friendly, and their use contributes positively to sustainable manufacturing practices.

In conclusion, the bearing industry relies on a range of components that must meet the required standards. Grinding wheels have proven to be essential tools in the production of bearings. They are efficient, reliable, and provide consistent finishes; all while extending the service life of bearings and reducing maintenance costs. Manufacturers within the industry should, therefore, leverage the benefits of grinding wheels to increase their production efficiency, quality, and cost-effectiveness.