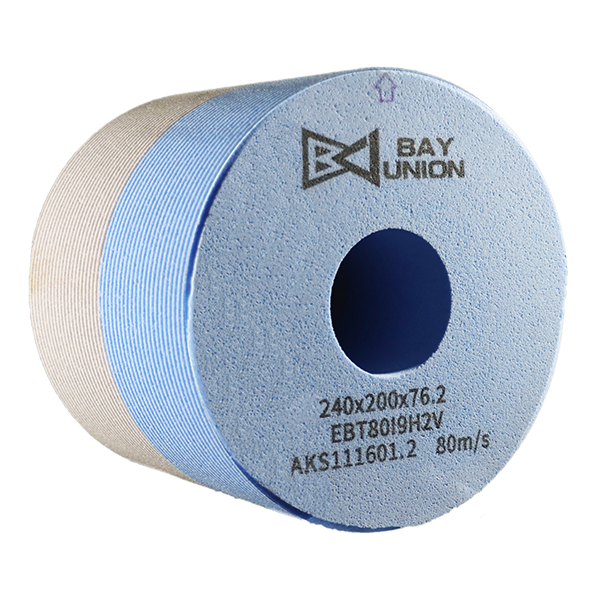

Continuous Generating Grinding

Bay Union utilizes high-quality microcrystalline abrasives to design the EBT/BFW/GFW series of continuous generation grinding wheels. These wheels are capable of overcoming challenges associated with surface hardening treatments on gears. They enhance gear grinding efficiency, reduce wheel wear, and extend tool life. The stability of gear profiles achieved with these wheels results in significant improvements in transmission performance, including reduced friction losses, higher transmission efficiency, and longer service life.

EBT80/EBT120

Utilizing the latest TG abrasives, the grinding wheels enhance grinding performance while maintaining a controllable surface roughness of RA0.4 or below. Compared to standard SG wheels, TG wheels also offer superior profile retention.

EBT-COMBO

As the demands for electric vehicle gears increase, with higher precision requirements for gear tooth profiles and finer surface roughness, standard gear grinding wheels often fall short of these standards.

When gears need to meet both substantial material removal and smooth surface finish requests, the EBT-COMBO grinding wheel offers the most effective solution. It features an efficient rough grinding entry for substantial material removal and a finishing exit that meets higher surface roughness standards, making the grinding process more efficient and effective.