7 Key Benefits of ID Grinding for Precision Manufacturing

Introduction

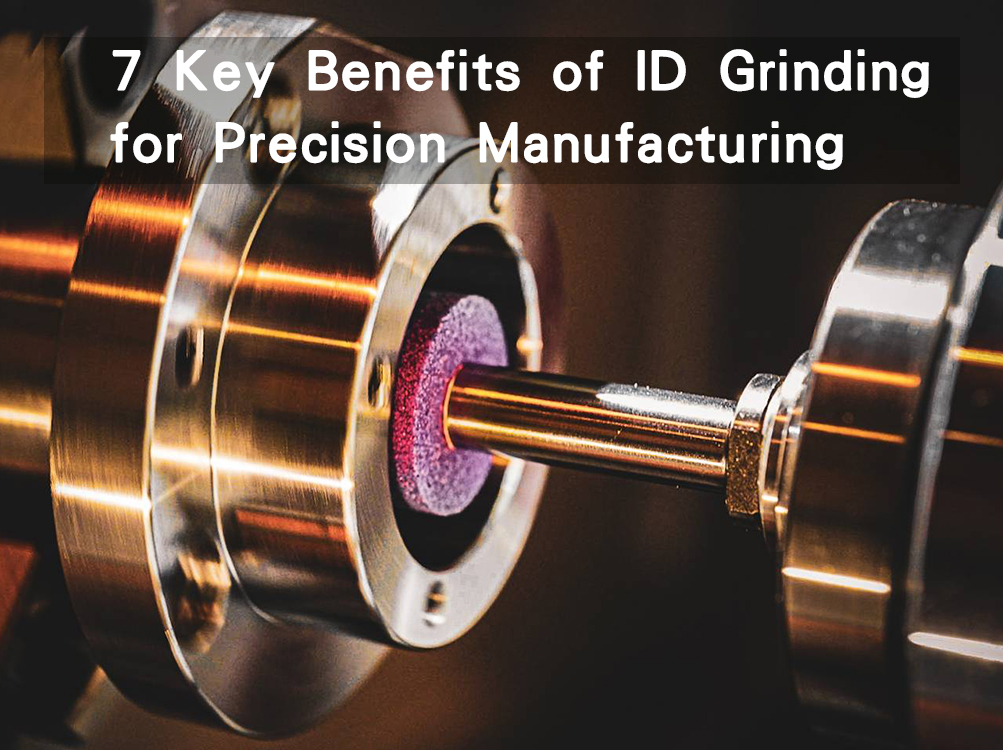

Internal Diameter (ID) grinding is a precision machining process used to produce highly accurate internal surfaces and finishes. This versatile grinding technique is essential for industries requiring extreme precision, such as aerospace, automotive, and medical device manufacturing. In this article, we explore the key benefits of ID grinding and why it's an optimal solution for various industrial applications.

1. Superior Accuracy and Precision

One of the main advantages of ID grinding is its ability to achieve extremely tight tolerances. It produces precise internal dimensions and smooth finishes, which is critical for components that must fit perfectly or move freely without excess friction. The accuracy achieved by ID grinding makes it ideal for producing parts like gears, bearings, and engine components, ensuring reliable and efficient performance.

2. Versatility for Complex Geometries

ID grinding is versatile and suitable for grinding cylindrical, conical, or complex-shaped internal surfaces. This flexibility allows manufacturers to use ID grinding for a wide range of components that require specific internal dimensions and geometries. This versatility is especially beneficial for applications in aerospace and automotive, where parts often have unique, intricate internal profiles.

3. Extended Component Lifespan

Components that undergo ID grinding benefit from improved surface integrity, leading to increased durability and lifespan. The process reduces the presence of surface defects, which minimizes the risk of cracks and other weaknesses developing over time. This is crucial for parts subjected to heavy loads or extreme operational conditions, such as those in industrial machinery or medical devices.

4. Efficient Material Removal

ID grinding is an efficient method for removing excess material from the internal surfaces of a part, particularly for hard or heat-treated materials. The grinding process allows for rapid removal of material while maintaining tight control over the final dimensions. This efficiency helps manufacturers achieve desired specifications quickly, reducing lead times and production costs.

5. Compatibility with a Wide Range of Materials

ID grinding is compatible with a variety of materials, including metals such as steel, aluminum, titanium, and even hard alloys. This adaptability ensures that ID grinding is suitable for producing parts used in numerous industries, from aerospace to medical equipment. Whether it's a hardened steel bearing or a titanium aerospace component, ID grinding can provide a precise internal finish.

6. Customization and Specialized Applications

ID grinding can be tailored to suit specific applications. Specialized grinding wheels and custom fixtures can be used to accommodate unique part designs or achieve specific finishes. This customization ability makes ID grinding suitable for high-value, low-volume production runs or for highly specialized components that must meet exacting requirements.

7. Automation and Modern Advancements

Recent advancements in ID grinding technology have led to greater automation, allowing for increased efficiency and consistency in the grinding process. CNC ID grinding machines provide better repeatability and accuracy, helping manufacturers reduce human errors and improve quality. Automated ID grinding is perfect for large-scale production, where consistency and reliability are key to meeting industry standards.

Bay Union's Specialized Internal ID Grinding Wheels

Bay Union offers specialized Internal ID Grinding Wheels designed to meet the precision requirements for various industrial applications. These grinding wheels are ideal for achieving precision and surface roughness on hard and brittle steels, especially when processing taper, deep, or blind holes. Their construction allows for effective stock removal and efficient heat discharge, critical for maintaining accuracy in small internal spaces.

Conclusion

ID grinding is an invaluable machining technique for producing precise internal dimensions, enhancing component longevity, and supporting complex geometries across a variety of materials. At Bay Union, we are dedicated to providing cutting-edge grinding solutions that meet the highest standards of quality and efficiency. Our Internal ID Grinding Wheels are designed to deliver the precision needed to excel in modern precision manufacturing.

For more information about how ID grinding can meet your precision needs, explore our range of solutions and connect with our experts today. Let Bay Union help you achieve manufacturing excellence with cutting-edge grinding technologies.