Cylindrical Grinding Wheels: Precision Shaping Tools

Introduction

Cylindrical grinding wheels are essential tools in the precision shaping of round components, ensuring high accuracy and surface finish. These wheels are commonly used in various industries, including automotive, aerospace, and manufacturing, where exact tolerances are critical. Cylindrical grinding wheels are designed to provide smooth, consistent grinding of cylindrical surfaces, helping to produce parts that meet stringent specifications.

Characteristics of Cylindrical Grinding Wheels

Cylindrical grinding wheels are characterized by their ability to deliver precise and consistent results. Key features include:

- High Precision: These wheels are engineered to achieve tight tolerances, making them ideal for applications where accuracy is paramount.

- Surface Finish Quality: The abrasive material used in these wheels provides a smooth finish, essential for components that require a high degree of polish.

- Durability: Constructed with high-quality abrasive materials, cylindrical grinding wheels are designed to withstand rigorous use, offering long-lasting performance.

Applications of Cylindrical Grinding Wheels

- Automotive Industry: Used in the production of engine components, gears, and other parts that require exact dimensions.

- Aerospace Sector: Essential for manufacturing high-precision parts that need to withstand extreme conditions.

- General Manufacturing: Applied in the production of various cylindrical parts, from machine components to tools, where precision and durability are crucial.

- Tool and Die Making: Ideal for shaping and maintaining cylindrical tools and dies, ensuring they meet exacting standards.

Selecting the Right Cylindrical Grinding Wheel

Choosing the right cylindrical grinding wheel depends on several factors, including the material being processed, the required surface finish, and the specific application. It is important to consider the wheel's grit size, bond type, and abrasive material to achieve the desired results.

The Role of Bonding and Grit in Performance

The performance of cylindrical grinding wheels is significantly influenced by the bonding material and grit size. The bond holds the abrasive grains together and determines the wheel's hardness and flexibility. Common bonds include vitrified, resin, and metal, each suited to different applications. The grit size, which can range from coarse to ultra-fine, affects the surface finish and material removal rate. Coarser grits are used for rapid material removal, while finer grits provide a smoother finish, crucial for high-precision work.

Advanced Applications in Modern Manufacturing

In modern manufacturing, cylindrical grinding wheels are indispensable for achieving high levels of precision and efficiency. In the production of high-performance automotive components, these wheels are used to grind crankshafts, camshafts, and transmission shafts to exact specifications, ensuring the reliability and performance of the vehicles. In aerospace, they are employed in the production of turbine shafts and other critical components that must endure extreme operational conditions. The use of advanced materials in these industries, such as titanium and superalloys, requires grinding wheels that can maintain their performance under challenging conditions.

Product Range and Versatility

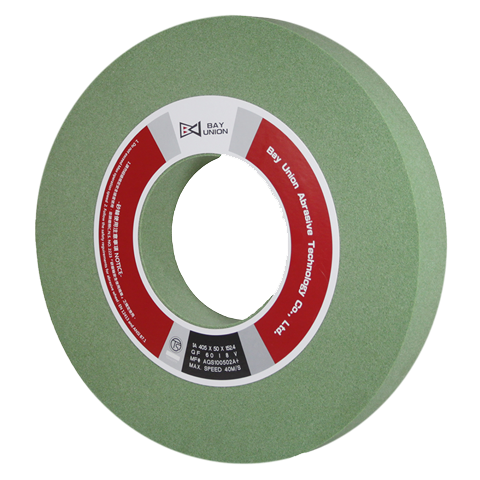

Bay Union offers a comprehensive range of cylindrical grinding wheels, designed to cater to various industrial needs. The product lineup includes wheels with different grit sizes, bond types, and abrasive formulations, tailored to suit specific materials and precision requirements. Whether you're working with hardened steel, superalloys, or other challenging materials, Bay Union's grinding wheels are engineered to provide optimal performance, enhancing productivity and quality in manufacturing processes.

Commitment to Continuous Improvement

Bay Union is dedicated to continuous improvement in grinding technology. We invest in research and development to create products that not only meet current industry standards but also anticipate future needs. By staying at the forefront of innovation, we ensure that our cylindrical grinding wheels offer superior performance, durability, and efficiency in every application.

Conclusion

Cylindrical grinding wheels are indispensable tools in achieving precision and accuracy in manufacturing. With their ability to produce high-quality finishes and maintain tight tolerances, they play a crucial role in various industries. Bay Union’s cylindrical grinding wheels offer the durability, precision, and performance required for demanding applications. Explore our range of grinding solutions and discover how we can help you enhance your production processes.

For more information and to find the right grinding solution for your needs, explore our product series and connect with our team of experts. Let Bay Union provide you with the tools you need for precision shaping and manufacturing excellence.