Continuous Generating Grinding of Gears

Advancements in continuous grinding technology have led to a high degree of automation and digitization in gear manufacturing, profoundly impacting the gear manufacturing process and directly enhancing the efficiency and reliability of mechanical transmission systems.

The integration of advanced gear grinding equipment with real-time monitoring systems enables manufacturers to achieve precise control over gear shape, size, and surface accuracy. This trend not only increases production efficiency but also ensures gear consistency and high quality.

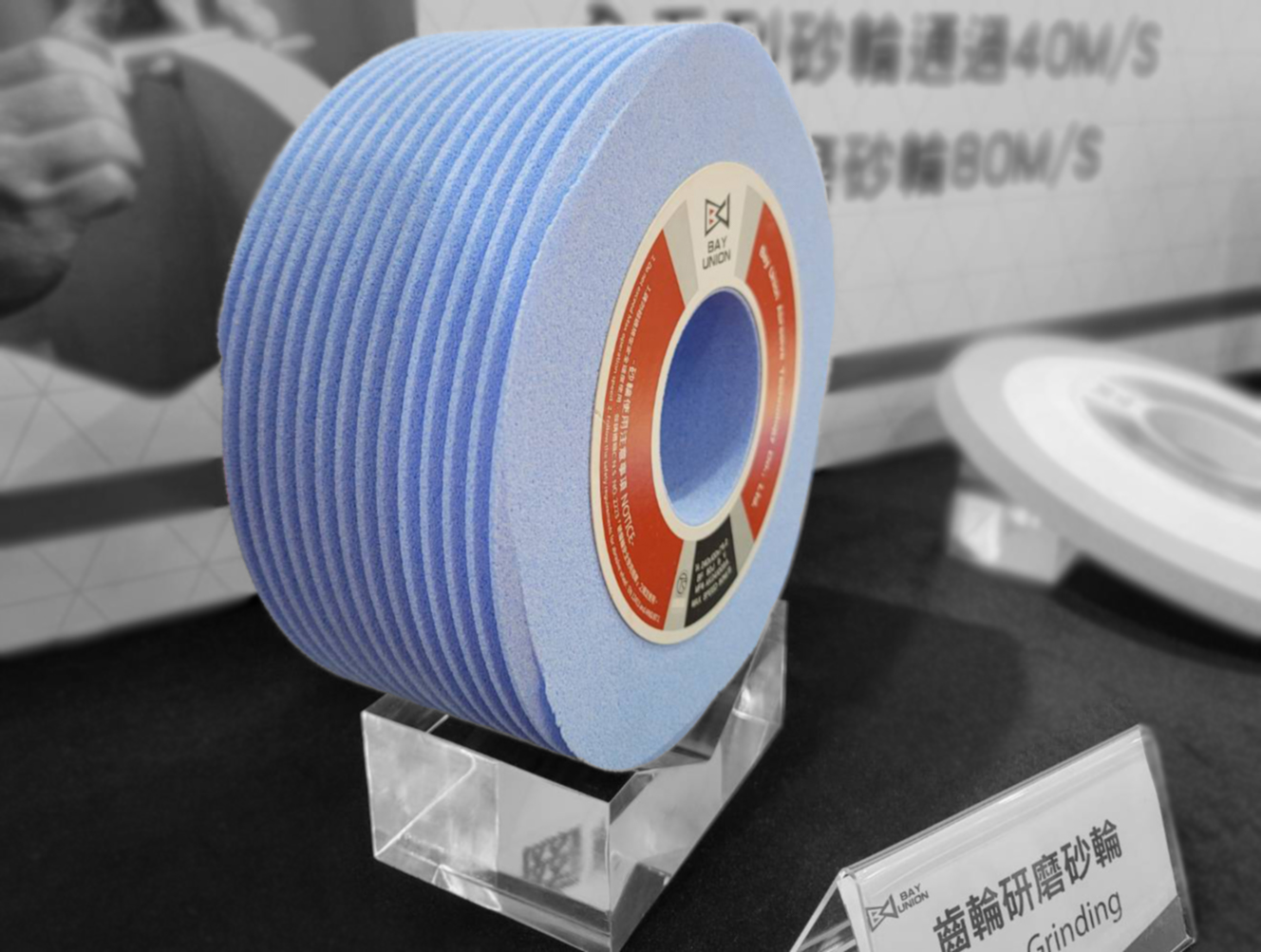

We use high-quality SG abrasives to produce our continuous generating grinding wheels: the BFV series. These wheels can overcome the challenges posed by surface hardening (such as induction hardening, nitriding, or coating treatments) of gears, enhancing gear grinding efficiency while reducing wheel wear and extending service life. The stability of gear curves significantly improves transmission performance, leading to lower friction losses, higher transmission efficiency, and longer service life.