Grinding Camshaft and Crankshaft: The Advantages of Precision Grinding

Grinding camshaft and crankshaft is a crucial process in the manufacturing of engines and other mechanical components. These components require high precision grinding in order to function effectively, efficiently, and durably. Incorrect grinding or a poorly ground component can lead to poor functionality, failures, and even accidents. This is why it is important to work with a professional grinding wheels manufacturer like BAY UNION.

So, what is camshaft and crankshaft grinding? Camshaft grinding is the process of shaping a camshaft's lobes and journals in order to produce a geometrically precise and faithful replication of the original cam's lift and duration. Crankshaft grinding, on the other hand, refers to the process of grinding the shaft and journals of a crankshaft to restore it to its original dimensions and tolerances.

In this article, we will delve into the advantages of precision grinding camshaft and crankshaft and some of the factors that contribute to this process.

Precision Grinding Improves Performance

The use of precision grinding wheels in the manufacturing of camshaft and crankshaft delivers improved accuracy, repeatability, and reliability, all of which are vital to the performance of the engines. Precision grinding produces exceptional dimensional and geometric consistency of the cam and crank parts, which leads to improved performance, durability, and longevity. It also helps to ensure that the engine runs with minimal vibration and noise.

Precision Grinding Delivers Improved Surface Finish

One of the key advantages of precision grinding is improved surface finish. The grinding process helps to remove any surface defects, scratches, or indentations. By removing these imperfections, the grinding process is instrumental in achieving a smooth and even surface, which is required for optimal function. In the case of camshaft grinding, the surface finish has a direct impact on the precision and efficiency of engine performance. A smooth surface allows the camshaft to ride smoothly on the bearings, reducing wear and tear and allowing the engine to run more quietly.

Precision Grinding Enhances the Durability of Camshaft and Crankshaft

Due to the high stresses that are placed on camshaft and crankshaft parts, it is important to ensure that they are of the highest quality and durability. Precision grinding allows for the manufacture of camshafts and crankshafts that are highly durable and capable of withstanding high levels of stress and wear over time. This is vital to the longevity of an engine.

Factors that Contribute to Successful Camshaft and Crankshaft Grinding

Precision grinding of camshaft and crankshaft requires specialized equipment and skilled personnel. Some of the factors that contribute to effective grinding include:

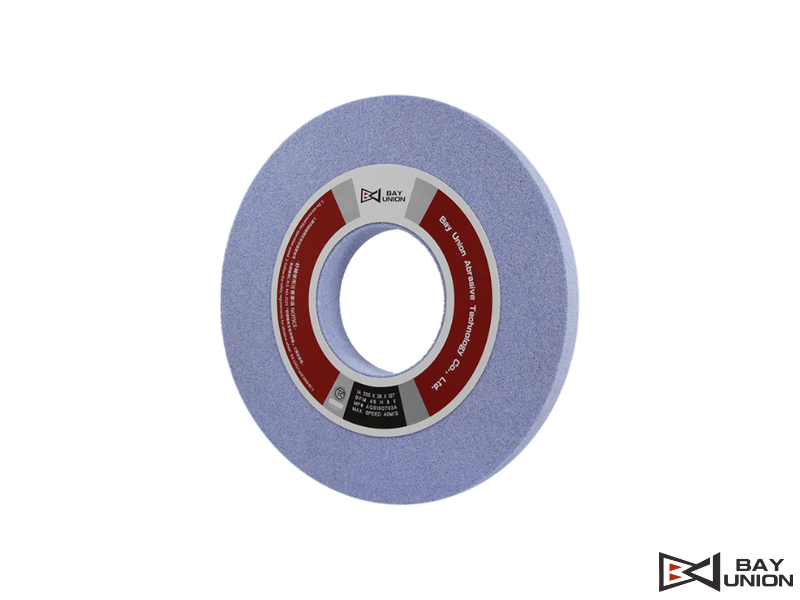

The use of high-quality grinding wheels that are able to remove material quickly while maintaining a consistent finish.

Precision measurement tools to ensure that the geometry and dimensional accuracy of the camshaft and crankshaft are correct.

The use of a coolant to prevent overheating and maintain the grinding wheel's effectiveness.

The selection of the right grinding parameters, including the grinding speed, feed rate, and grinding depth.

Highly skilled technicians who are experienced in the art of precision grinding.

Conclusion

In summary, grinding camshaft and crankshaft is a crucial process in the manufacture of automotive engines and mechanical components. Precision grinding is a process that involves the use of high-quality grinding wheels, specialized equipment, and skilled personnel to deliver exceptional dimensional and geometric consistency, improved surface finish, and durability. At BAY UNION, we are committed to delivering high-quality grinding wheels that are specifically designed to meet the needs of the automotive and mechanical industries. Contact us today to learn more about our product and services.