- NEWSNEWS

- EXHIBITIONEXHIBITION

What are Camshaft and Crankshaft, and What They Do? How to Grind Camshaft & Crankshaft?

Camshafts and crankshafts are two core components of an internal combustion engine. Camshafts control the opening and closing of the engine's valves, which are responsible for the intake and exhaust of air and fuel into the engine, while crankshafts convert the linear motion of pistons into rotational energy. This article will explore in greater detail what camshafts and crankshafts are, how they work, and how they are ground to ensure the proper functioning of an engine.

What is a Camshaft?

A camshaft is a cylindrical component that is responsible for controlling the opening and closing of the engine's valves. A typical camshaft has a series of projections, called lobes, that are designed to press down on pushrods or lifters that, in turn, activate the engine's valves. The shape of the camshaft's lobes determines the way in which the valves open and close. Camshafts are typically made from cast iron or steel, and are installed in the engine block parallel to the crankshaft.

What is a Crankshaft?

A crankshaft is a component that converts the linear motion of pistons into rotational energy. Crankshafts are typically composed of a series of crankpins and main bearings that are arranged in a circular pattern. As the pistons move up and down in the engine, they rotate the crankshaft, which transfers its energy to the transmission and ultimately the wheels. Because crankshafts are subject to large amounts of torque and rotational stress, they are typically made from high-strength alloys, such as forged steel.

How Do Camshafts and Crankshafts Work Together?

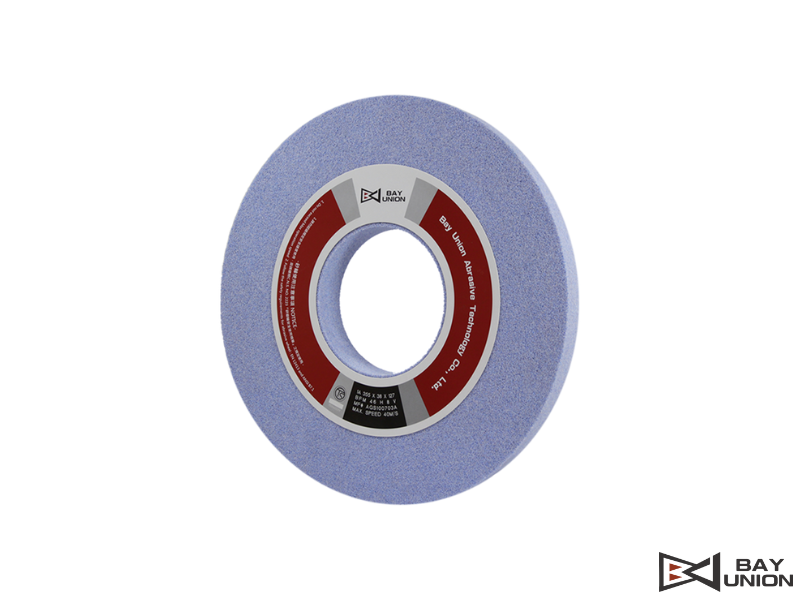

To ensure the optimal performance of an engine, the meticulous grinding of camshafts and crankshafts is a critical step. Bay Union, a leading name in the industry, plays a vital role in this process, ensuring that these essential engine components meet precise specifications. The grinding of camshafts and crankshafts involves the strategic removal of minute amounts of material to achieve a smooth, flawless surface, a task carried out with precision using either hand-held grinders or specialized grinding machines, with a special emphasis on Bay Union's Surface and Cylindrical Grinding Wheels.

The Grinding Process: Precision Redefined

The primary objective of grinding camshafts and crankshafts is to guarantee that they are perfectly round, straight, and devoid of any imperfections that could compromise their functionality or lead to premature wear. Bay Union employs advanced techniques in this process, with a focus on centerless grinding and plunge grinding, using their specialized Surface and Cylindrical Grinding Wheels.

1. Centerless Grinding:

This technique involves feeding the camshaft or crankshaft through a set of grinding wheels arranged parallel to each other and to the shaft, using Bay Union's precision-engineered Surface Grinding Wheels. Spinning at high speeds, these grinding wheels meticulously remove material from the shaft's surface. The shaft is carefully guided through the grinding wheels using a series of rollers or support devices, ensuring it is ground to the precise shape and size required for optimal performance.

2. Plunge Grinding:

In scenarios where the shafts are too short or too small for centerless grinding, plunge grinding comes into play. This method entails directly feeding the camshaft or crankshaft into a grinding wheel, using Bay Union's specialized Cylindrical Grinding Wheels, which adeptly removes material from the shaft's surface. It's a technique tailored for specific shaft dimensions that may not be suited for centerless grinding.

Why Precision Matters:

Camshafts and crankshafts are the heartbeat of an internal combustion engine, working synchronously to ensure smooth and efficient operation. The precision achieved through grinding guarantees that these components are not just round and straight but also free from defects that could compromise their longevity. Premature wear or failure is mitigated through the meticulous removal of material to create an impeccably smooth surface.

Bay Union's Commitment to Excellence:

As a prominent player in the industry, Bay Union brings a commitment to excellence in every aspect of the grinding process. Their expertise lies in delivering camshafts and crankshafts that meet the highest standards of precision, ensuring engines are efficient, reliable, and enduring, thanks in part to the quality and precision of their Surface and Cylindrical Grinding Wheels.

Conclusion:

In the intricate dance of an engine's internal components, the role of perfectly ground camshafts and crankshafts cannot be overstated. Bay Union, with its dedication to precision and quality, stands as a cornerstone in this process. By employing advanced grinding techniques such as centerless grinding and plunge grinding, using their high-quality Surface and Cylindrical Grinding Wheels, they contribute significantly to the production of engines that are not just powerful but also dependable.

For more information on Bay Union and their range of grinding wheels, including Surface and Cylindrical Grinding Wheels, visit Bay Union's website. As engines evolve, Bay Union remains at the forefront, ensuring the heart of every machine beats with precision and reliability.